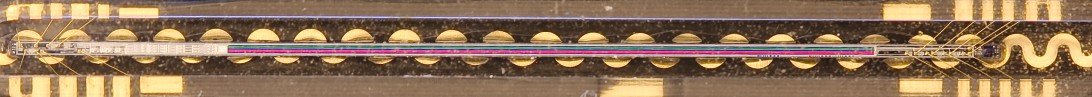

There are rumours abound that eventually the small 2-pin plug and socket connection for the extruder heater eventually fails. Mine did at the worst possible time – at the 12 hour point of a 14 hour print. (Thankfully the print was mostly recoverable.) Pictured below is the plug that is prone to failure.

Unfortunately, no indication was given that the extruder had lost power, only that the printer continued to print whilst no filament was extruded. Initial thoughts were that the Da Vinci had some sort of bug that appeared after such a long printing process.

However, the plug was identified as the culprit when I attempted to make a new print. During the bed and extruder heating phase at the beginning of the print, the bed’s temperature rose, but the extruder remained at ambient temperature.

To confirm that the plug was faulty, it was disconnected and the two pins were adjusted. When reconnected, the temperature began to rise again, but would plateau and fall again. This process of adjusting the pins was repeated several times and the extruder temperature would rise.

When it looked likely that the problem was fixed I fiddled with the plug again and felt the plug connection to be hot to touch. A hot joint was developing inside the plug! Hot joints arise in power connections with high current draw. Some quick measurements of the extruder voltage (12 VDC) and the extruder heater resistance (4.9 ohm) reveals that 2.4 A of current is drawn by the extruder’s heater.

The hot joint must have been caused by me adjusting the plug’s pins. My adjustments have resulted in the pins and sockets not mating correctly and there being high contact resistance. As the 2.4 A flows through this contact resistance, the temperature rises. It is likely that the plug and socket would have failed again.

A new solution was required. A spare DC jack and socket was found and after about 45 mins the replacement connection was completed. I couldn’t find a datasheet or any details on the maximum current carrying capacity of a DC jack and socket but intuition tells me that it should suffice. The new arrangement still allows for quick release.

Note that the supply side of the connection is the female connection and the centre pin is 12V positive (the polarity was measured earlier).

If you find your extruder unexpectedly fails to heat check the quick release plug and socket. Be careful if you adjust the pins as you may cause more damage if you create a hot joint in the connection. It is probably best to replace the stock quick release connection with a more robust and substantial plug and socket to ensure reliable printing.