A recent project involved using an electric skillet to reflow solder some APA102C RGB LEDs to a PCB. The aim was to make a device similar to the Adafruit Neopixel Strips, but arranged in a 3×3 square and using the APA102C LEDs.

Honestly, each board that was made was a fail. Electrically, they all worked correctly. The failure was during the manufacturing stage – reflow soldering very small SMD components.

Just as an aside, Adafruit Neopixel devices use WS2812B LEDs which have some very strict timing requirements – this can be problematic for some devices that use software interrupts. Whereas, the APA102C LED is a chip that does not suffer from strict timing.

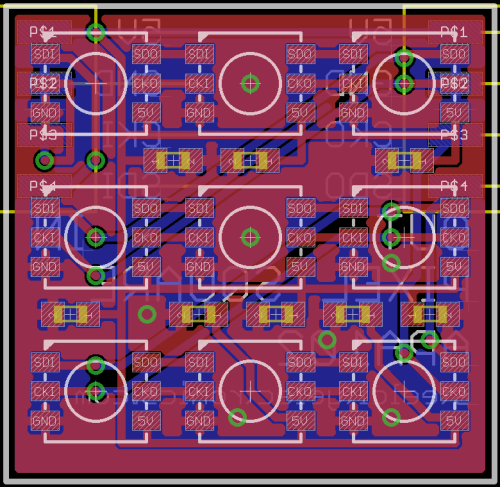

Each small PCB, contains 9x APA102C SMD LEDs and 8x 0.1uF 0603 ceramic capacitors for power supply decoupling. Each APA102C LED is the large white square with white circle. Between the rows of the APA102C LEDs are the SMD pads for the 0603 size capacitors.

0603 (imperial) sized components are small, about 1.6mm x 0.8mm in size. Their small size was known from the outset, but their tiny size would allow them to easily fit between the rows of APA102C LEDs. Allowing the overall size of the PCB kept to a minimum.

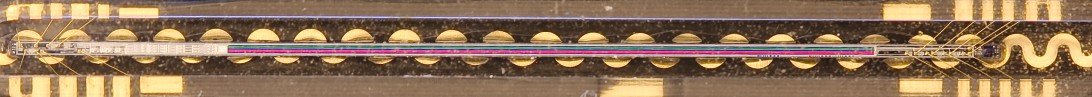

Unfortunately during reflow, problems began. Because of their small dimensions, 0603 components also have a small mass. So, if both solder pads for the component do not melt at the same time, the component will be pulled towards one of the solder pads due to surface tension. When this occurs, the component can flip upright and tombstone.

The tombstone description is a good description. Both the component is standing vertically, like your dead relative’s granite monument, and that your device is dead or requires some serious hand rework (defeating the point of SMD manufacture).

I recently showed a bunch of dead boards to a friend (Matt, your website’s link is broken so I can’t cross link for you) and he made a close observation. All the capacitors pulled towards the SMD pad which was connected to a smaller trace. This suggests, that the SMD pad’s thermal design was inadequate or that my dodgy skillet reflow method was unable to evenly heat each solder pad simultaneously.

So, what lessons have been learned, skillet reflow of 0603 capacitors is most likely going to fail. A skillet is probably not the best tool for reflow soldering such tiny devices.

Larger sized SMD components will be tried in the next revision of the design. There maybe some room for improvement with the temperature control of the skillet too.

If you’ve had success reflow soldering tiny SMD components without a specialised reflow oven, leave a comment below.

I am going to design a five LED strip of APA102C’s and can’t figure out if I need to use a bypass capacitor at each APA102C like when using WS2812’s. Every strip and PCB design using APA102C’s don’t have any bypass capacitors in the design, including ones designed by Adafruit.

I am a bit confused and don’t know if I actually need them in my PCB design. Did you notice any difference when using bypass capacitors or not? Thanks for any advise you might have.

Jason

LikeLike

Hey Jason,

I used the bypass capacitors because of a ‘rule of thumb’ you should decouple at every IC (the apa102c LEDs have a small IC internally). However, the APA102C datasheet does not show the need for bypass capacitors.

I found that my boards worked fine without bypass caps.

If your project is a prototype, give it a try with no capacitors. If you find some buggy behaviour with the LEDs when testing then install some capacitors.

All the best,

Tim

LikeLike